About us

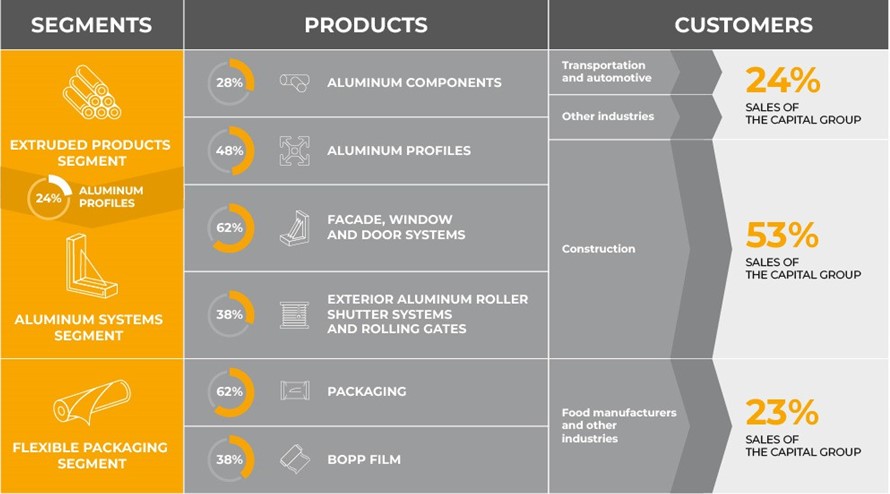

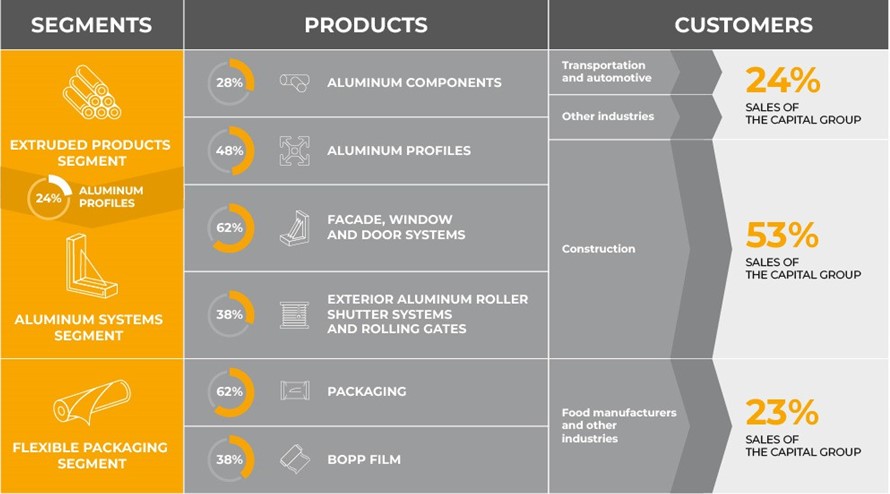

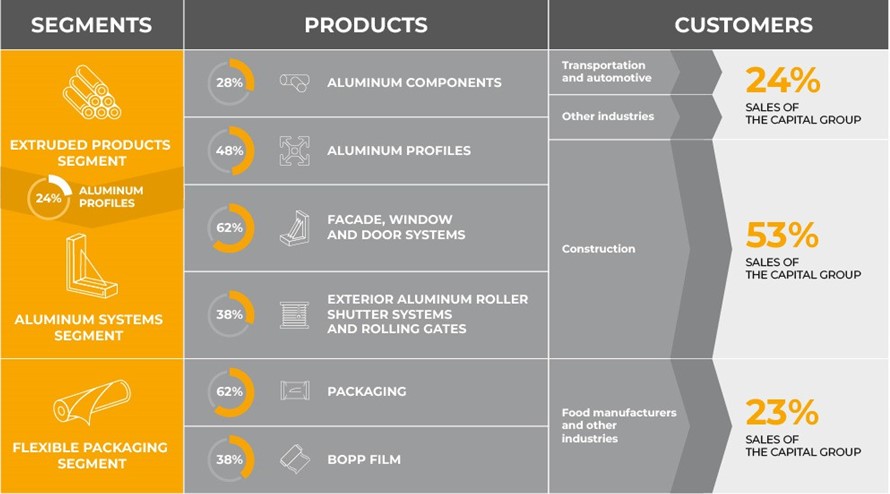

Grupa Kęty S.A. is a parent of the Capital Group of Grupa Kęty S.A. , composed of following three business segments:

The Capital Group has 14 foreign companies which sell products to over 4,500 customers on over 60 markets. In 2024, nearly half of the PLN 5.1 billion Capital Group’s sales income was invested outside Poland, specifically on the European market, where 46% of sales are generated, including 39% in the European Union member states, such as Germany, Czech Republic, Italy, Netherlands, Romania, Belgium and Austria. Outside Europe sales are generated in the United States, Vietnam, Saudi Arabia and the United Arab Emirates, among others.

In 2024, in reference to the acquisition of SELT Sp. z o.o., whose results were consolidated within the ASS since September 2024, the Capital Group gained the production complexes belonging to the company in Opole and Rogów Opolski, furnished with modern machinery, including comprehensive machining centre with 36 CNC machine tools, 3 lasers, 2 machines for high pressure aluminium casting, 16 profiling machines used in coated aluminium strips forming for external blinds louver blades or galvanised pipes, 290 dies for aluminium profiles extrusion, 46 injection moulds for the production of PVC details and 2 powder coating workshops.

The Capital Group processes materials in the following key processes: primary aluminium and scrap aluminium melting, billets casting, profiles extrusion from aluminium and aluminium-alloy billets, mechanical machining, welding, anodising, powder coating, manufacturing of plastic films, printing, laminating, metallisation, cutting, assembly and picking-up of architectural systems elements and sun protection products for the construction industry.

Apart from manufacturing processes, the Capital Group companies carry out activities related to products research and development, introduction of new technologies, and optimisation of the existing technologies. These include, among other things, analyses of the chemical composition of materials, strength tests, metallographic tests, spatial measurements, ultrasonic tests, electrical conductivity measurements, specific tests for the automotive industry and the implementation of new packaging categories.

Waste management activities consist primarily in transferring as much waste as possible to entities which specialise in recycling. Virtually 100% of the aluminium waste generated in production processes is remelted within in-house operations (at the Foundry Plant) in order to obtain full-value semi-product for further processing.

Finished products are packed and stored in order to prepare them for distribution.

The Capital Group avails of transportation services (with a clear dominance of road transport) distributing products in most cases directly to customers.

The primary natural resource on which the Capital Group’s operations are based is bauxite, a sedimentary rock that is a mixture of minerals containing various concentrations of hydrated aluminium oxides. Its mining and subsequent refining with cryolite produces aluminium, which the Capital Group obtains in the form of: primary aluminium, sheets, alloys, scrap, billets, foil and other semi-products and finished materials.

Apart from aluminium profiles obtained mainly from the Extruded Products Segment, accessories and semi-products such as hardware, gaskets and glass for the production processes at the Aluminium Systems Segment are sourced from suppliers. A great deal of components used are made of steel.

The Flexible Packaging Segment uses various types of plastic films and granulates (polyethylene, polypropylene). The Flexible Packaging Segment sources major categories of materials, such as printing, universal and greaseproof papers, paints, adhesives and binders, from the segment suppliers.

The Capital Group withdraws water and uses it primarily in the chemical and thermal processing of aluminium. These processes include painting, anodizing, rinsing and cooling. The sources of water are water supply networks (about 30% of withdrawal) and own intakes (about 70% of withdrawal).

The energy used mainly in production processes comes from the combustion of natural gas from the national transmission networks. Processed fossil fuels are a raw material used in the production of granulates for the Flexible Packaging Segment.

The Capital Group also sources various substances, chemical compounds and elements that are used, primarily, in the production of extruded products (acids, bases, technical gases, alloying elements).

Among the entities within the value chain whose operations are not directly related to the business model of the Capital Group but are important for the operation of the Capital Group are companies whose employees provide services in the scope listed in the supporting activities section of the table further below.

| Segment | Company | Products | Key customer categories – industries | Key sales markets | Sustainability related goals of the Group |

|---|---|---|---|---|---|

| Extruded Products Segment (EPS) |

|

Production and sales of:

|

Construction, automotive, transport (including electric vehicles), railway, electrical engineering, household equipment, advertising, tourism. | Poland, Germany, Czech Republic, Austria, Italy, UK, Slovenia, Ukraine, France, Hungary. |

|

| Aluminium Systems Segment (ASS) |

|

Production and sales of:

|

Construction | Poland, UK, Czech Republic, Romania, Germany, Belgium, Netherlands, Slovakia, Hungary. |

|

| Flexible Packaging Segment (FPS) |

|

Production and sales of:

|

Food concentrates, confectionery, fats, dairy, meat, cold meats, pharmaceuticals, chemicals. | Poland, Netherlands, Germany, Hungary, Ukraine, Czech Republic, Italy, Switzerland. |

|

In 2024, the Group recorded slight changes in customer groups and markets served, which resulted mainly from the acquisition of SELT Sp. z o.o.

In December 2020, the Management Board of Grupa Kęty S.A. presented the Development Strategy of Grupa Kęty S.A. Capital Group for the years 2021–2025, which was later updated in July 2021, as described in details in Section 4 Capital Group development strategy of the Report of the Management Board of Grupa Kęty S.A. on the operations of the Company and the Capital Group.

| Upstream value chain | ||

|---|---|---|

| Non-renewable natural resources (mineral resources): | Basic materials used in manufacturing processes: | Auxiliary materials, substances and chemical mixtures: |

Renewable raw materials: water, wood. |

EPS:

ASS:

FPS:

|

|

| Own operations | ||

|

EPS:

|

ASS:

|

FPS:

|

|

Downstream value chain

|

||

| EPS:

Customers in the construction and interior furnishing industry (more than 40%), transportation and automotive (more than 20%), home appliances, electrical engineering and machinery, sports and recreation, and others. |

SSA:

Customers in the construction industry (100%).

|

SOG:

Customers in food production industry (over 50%), BOPP films (nearly 40%).

|

| Supporting activities | ||

| IT services Security and cleaning services Insurance Consulting and training services Legal services |

||